Description

The feeder is designed for the submission and dear, or granular materials dosing stored in silos or bunkers. The material is fed to the stage, part of the výsypkou silos feed upon rollers so that the pressure effect of the material was eliminated. The implementation of discharge chute and its height above the waist ensure samouzavírání material flow. The front of the forehead of the dump (in the direction of removing material) is provided with an adjustable damper that allows to set the height and shape of the figures on the sheet feeder. Also the shape of the side discharge chute is designed so as to avoid propadávání of the material and to blackmail the waist under the side direction. The material is vynášen the waist and weighed the weighing seat odavače. In addition to weighing the waist is sensed and its speed. The material flow is proportional to the load weighing stool and the speed of the belt.

Electronic feeder unit, in cooperation with frequency converter the motor transportation of the specified quantity of material or other required parameters according to customer's needs. Also cooperate, if necessary, with a superior control system.

The use of the

Weighing and dosing of powder or granulated materials, submission to the mills, the manufacture of mixtures, etc.

The benefits of

Compact design, reliability, high accuracy, trouble-free operation, easy to set the parameters.

The parameters of the

| Bulk density of the material | 500 ÷ 2000 kg/m3 |

| The flowrate range of the material | see table the flowrate range mat. below |

| Max. dimension of grains | approx. 100 mm |

| The dimensions of the | see the dimensional diagram below |

| Error weighting | Max. 1% of Qnast |

| The level of outbound. signal | 12V or 20 mA |

| Max. the distance from the weighing electronics | 50 m |

| Range of working temperatures | -30 ° c ÷ + 50 ° c |

The range of flow rates

| PPV6 | PPV12 | PPV30 | PPV60 | PPV120 | PPV300 | |

|---|---|---|---|---|---|---|

| Flow [t/h] | 0.6 ÷ 6 | 1.2 ÷ 12 | 3 ÷ 30 | 6 ÷ 60 | 12 ÷ 120 | 30 ÷ 300 |

* If necessary the possibility of delivery in the version to 210 ° c.

* For execution with a ballast resistor.

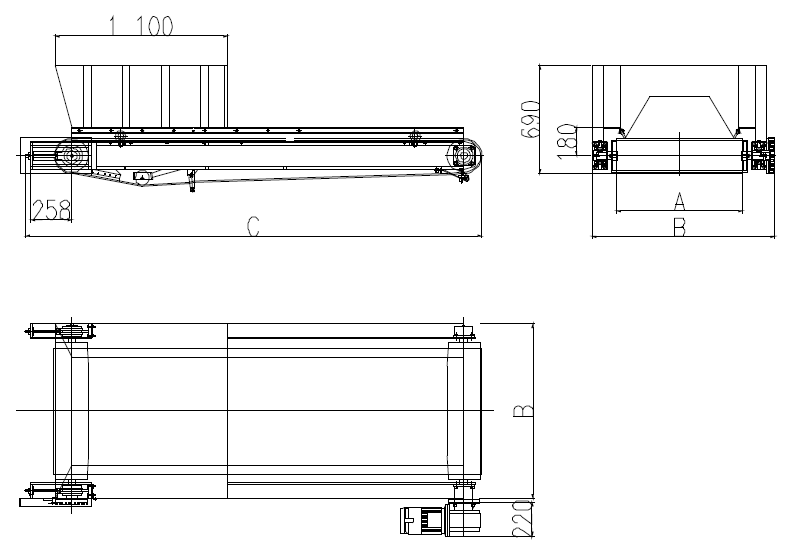

Dimensional schema

Basic dimensions

| Feeder type/size | And | (B) | (C) |

|---|---|---|---|

| APPV 6 | 500 | 850 | 3300 |

| APPV 12 | 650 | 1000 | 3300 |

| APPV 30 | 650 | 1000 | 3300 |

| APPV 60 | 800 | 1150 | 3300 |

| APPV 120 | 800 | 1150 | 3300 |

| APPV 300 | 1000 | 1350 | 3300 |

To download a prospectus in Adobe PDF format, click XX_pasovy vazici podavac APPV